R&D FIELDS

Assist on cutting edge product development

with Next Generation Semiconductor

Headspring carries the strength in developing high efficiency and miniaturization design with the usage of next-generation semiconductors (SiC, GaN). In addition, we have a wide range of technologies that are necessary for the development of power electronics equipment, optimizing power, electronics and control. These technologies are combined to support customer research and development.

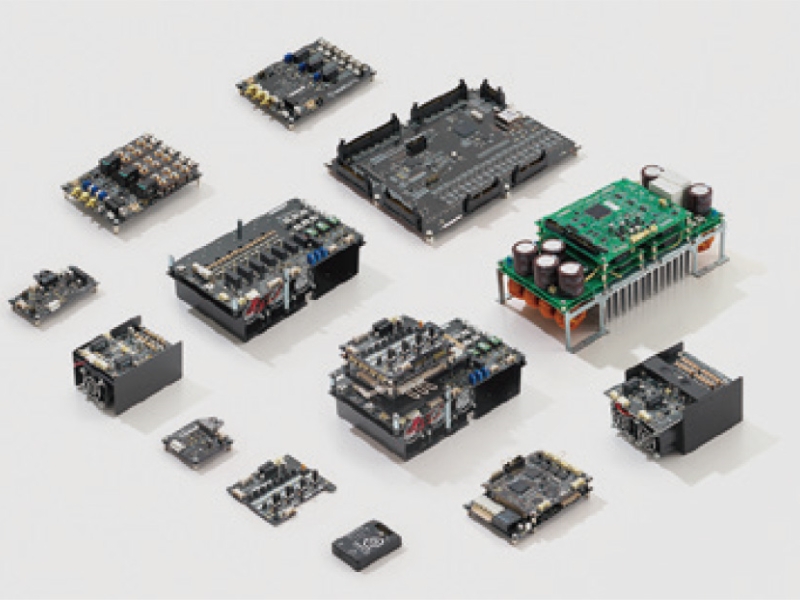

In addition, we have modularized hardware and software as technical assets, which can be used to reduce the development man-hours for customers. Besides of able to use these modules as functional prototypes, it is possible to seamlessly use assets in future product development.

Hardware/Software development

We are developing small, high-performance motor drivers using next-generation power semiconductors (SiC, GaN) and high-performance custom controllers equipped with various IO and communication functions. We have many achievements such as evaluation boards for power devices and various type of

pre-production prototyping circuits

Hardware Reference Cases

We have a wide range of development experience from fabricating R&D experimental products, Proof-of-concept (POC) unit, and pre-production prototyping.

- - Power device evaluation board

- - High frequency pulse generator with GaN

- - Multi-level inverter experimental equipment

- - Custom controller for MMC

- - High-power motor driver for robot

- Capacity range:1-20kW

- Voltage range:—DC800V/—AC400V (approximately)

Please contact us for more information related to power electronics customization.

Software development capability

We are experienced in power electronics software customization through FPBA logic and libraries.

Development results (example)

- - Grid interconnection software

- - Motor drive software

- - Digital power control software

- - Special gate signal generation FPGA logic

- - High frequency pulse output library

Communication method

- - CAN

- - Ethernet

- - Wi-fi

- - EtherCAT

- - RS422, 485, 232C

- - SPI etc.

Programming language

- - C

- - C#

- - C++

- - VHDL

- - Verilog

Development tools

We offer a set of development tools that enable you to create a power electronics experimental

environment with a combination of standard parts and a little customization. We can also construct

experimental facilities that combine these.

Overview

A high-end development tool that condenses the know-how of development professionals. The user can customize it freely by attaching design materials.

Hardware

- - Embedded controller for power electronics development

- - Multi-gate output controller

- - Circuit block with SiC power device

(Half bridge, H bridge, Three phase inverter) - - Circuit block with GaN power device

(Half bridge/Three phase inverter) - - Sensor board

- - Reactor board

- - SiC/GaN inverter experiment kit

Software

- - Development support kit

Library/GUI/HSDT-DP - - DAB library

- - Grid interconnection software

- - Motor drive software

Hardware and software combinations and customizations are also available.

Please contact us.

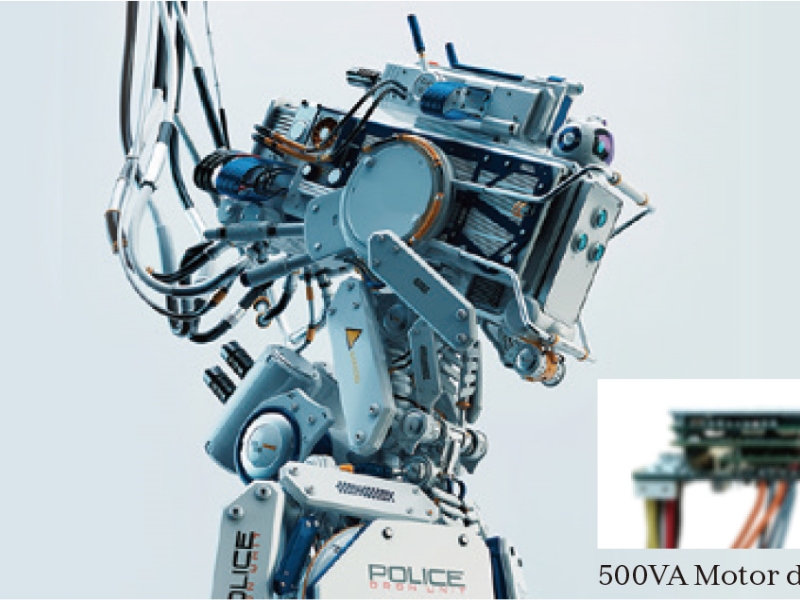

Motor driver for robot

A small and high output motor driver using SiC-MOSFET devices. The EtherCAT communication library used for robot control has also been developed.

Development results

We provide a wide range of support not only for power circuits but also for the development of controllers, control software, and communication functions.

Robot motor driver (inverter part) specification example

- Maximum input voltageDC300V

- Rated input currentDC25A

- Rated output currentAC15Arms

- Rated output capacity500VA

- Switching frequency100kHz max

- Dead time200ns min

- Isolation voltage1500V

- Current sensor circuit3ch

- Voltage sensor circuit1ch

Technical assets to use

- - Power Electronics Embedded controller

- - Library

- - SiC three-phase inverter

Our knowledge assets

We accelerate customer EV development and production using EV platform which integrate EV electrical equipment control system and Electric power control platform that reduces the burden of capital investment by sharing units and equipment in EV production plants.

Hardware Design

Software Design

Electronics &

Communication

System Design

R&D FIELDS

Hardware Design

Software Design

Electronics &

Communication

System Design

INDUSTRIAL FIELDS

Hardware Design

Software Design

Electronics &

Communication

System Design

AUTOMOTIVE

BUSINESS DOMAIN

Hardware Design

Software Design

Electronics &

Communication

System Design

ENERGY FIELDS

Hardware Design

Software Design

Electronics &

Communication

System Design