AUTOMOTIVE

BUSINESS DOMAIN

Providing innovative solutions

using next-generation power semiconductors.

One of the key areas for realizing a sustainable society is the electrification of vehicles. In order to speedily apply the small-sized and high-efficiency power conversion technology that has been cultivated so far, using next-generation power semiconductors such as silicon carbide (SiC) and gallium nitride (GaN) to this field, We are promoting collaboration with Tokyo R&D. This will not only advance the development of innovative in-vehicle power converters, but will also provide test equipment and V2X solutions for major components including those parts, thereby contributing to the creation of future smart energy systems.

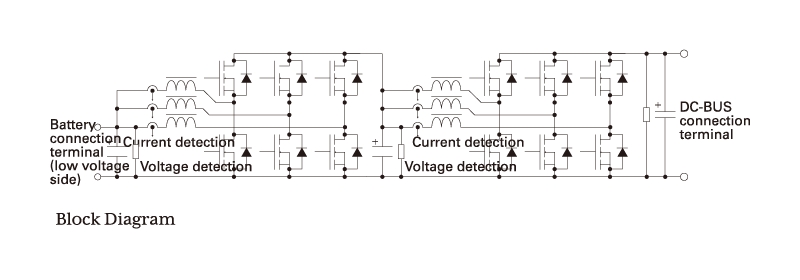

Automotive DCDC converter

We develop custom-made DCDC converters which supply power from high-voltage batteries to low-

voltage auxiliary machines such as lights and wipers.

It is characterized by its small size and high efficiency using next-generation power semiconductors (SiC,GaN). We support from prototypes in advanced development to mass production.

Development results

We are developing an insulated bidirectional DCDC converter for small EVs, construction machinery, and special vehicles.

Specification example

- Equipment capacity100kW

- Number of inputs2ch

- Number of outputs2ch

- High voltage side240 to 1000Vdc

- Low pressure side36 to 450Vdc

- Maximum input current± 560Adc

- Maximum output current± 420Adc

- Communication interfaceCAN

- Cooling methodWater cooling

- Insulation method DAB (Dual Active Bridge)

*Total development support including not only the power circuit but also the controller and control software.

Bidirectional in-vehicle charger with DCDC converter function

We develop a custom-made bidirectional on-board charger that can charge and discharge with one unit. Since AC power can be taken out, it is ideal for cases that require AC power in the vehicle such as a medical examination car. We support from prototype to mass production.

Development results

Development is in progress for small EV.

Specification example

- Equipment capacity6.6kWmax

- Charging side input voltage rangeAC90V to 240V

- Rated input voltage on the charging side AC100V/200V

- Battery side voltageDC200V—400V

- DCDC output current80A (5sec interval)

- DCDC rated current0 to 20A

- Operating temperature range-20 degrees to +60 degrees

- Storage temperature range -40 degrees to +80 degrees

Power conversion unit for quick charger

A power conversion unit for a quick charger that is the infrastructure of EV. By combining various types of units such as AC/DC converters, DC/AC converters, and storage batteries, it is possible to construct a power conversion system that supports various types of power systems or quick chargers.

Development results

We provide a wide range of support from system review, hardware design, embedded software design, and evaluation testing.

Specification example

- Power capacity50-200kW

- System side voltageThree-phase 200/400V

- Output voltageThree-phase 200/400V

- Battery voltageDC400—800V

Technical assets to use

- - Power ElectronicsEmbedded controller

- - Library

- - Power conversion module (SiC)

Our knowledge assets

We accelerate customer EV development and production using EV platform which integrate EV electrical equipment control system and Electric power control platform that reduces the burden of capital investment by sharing units and equipment in EV production plants.

Hardware Design

Software Design

Electronics &

Communication

System Design

R&D FIELDS

Hardware Design

Software Design

Electronics &

Communication

System Design

INDUSTRIAL FIELDS

Hardware Design

Software Design

Electronics &

Communication

System Design

AUTOMOTIVE

BUSINESS DOMAIN

Hardware Design

Software Design

Electronics &

Communication

System Design

ENERGY FIELDS

Hardware Design

Software Design

Electronics &

Communication

System Design